[Article]: What Are Load Cells? Types, Applications, and How They Work

Load cells are essential components in weighing systems, converting force or weight into an electrical signal. Found in everything from industrial scales to medical equipment, they provide accurate, reliable measurements of mass or force. This article explains how load cells work, the main types available, and where they are used.

What Is a Load Cell?

A load cell is a transducer that converts a mechanical force into an electrical signal. When a load or force is applied, the cell deforms slightly. This deformation is measured by strain gauges or other sensors, producing a signal that can be read and recorded.

Load cells are critical in ensuring weighing accuracy, safety, and compliance in industrial, commercial, and scientific environments.

How Does a Load Cell Work?

Most load cells operate based on the strain gauge principle. Strain gauges are bonded to a metal element inside the load cell. When force is applied, the element deforms slightly, causing a change in the resistance of the strain gauge. This change is converted into an electrical signal, which is proportional to the applied force or weight.

Main Types of Load Cells

There are several types of load cells, each suited for specific applications and mounting methods:

1. Compression Load Cell

Use: Weighbridges, tank and silo weighing

Features: Designed to measure a force applied in a downward direction

2. Tension Load Cell

Use: Crane scales, suspended weighing systems

Features: Measures force pulled in tension (opposite direction of compression)

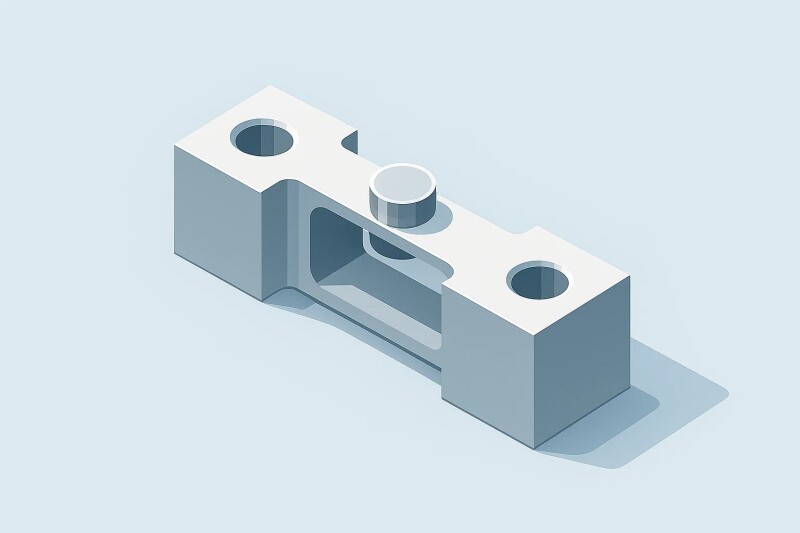

3. Shear Beam Load Cell

Use: Floor scales, platform scales, hopper weighing

Features: Compact, resistant to side loads and vibrations

4. Single-Point Load Cell

Use: Retail scales, bench scales, small platforms

Features: Accurate for off-center loads, ideal for small weighing applications

5. S-Type Load Cell

Use: Tension and compression applications

Features: Shaped like an “S”, versatile and easy to mount

6. Pancake Load Cell (Low-profile)

Use: High-precision testing, aerospace, automotive

Features: High accuracy and stability, low height design

7. Load Pins (Load Measuring Pins)

Use: Crane hooks, pulleys, winches

Features: Replaces mechanical pins to measure force directly in lifting applications

8. Canister Load Cell

Use: Heavy-duty truck scales, industrial tanks

Features: High capacity and robust construction

Common Applications of Load Cells

- Industrial weighing: Scales, weighbridges, batching systems

- Logistics: Onboard truck weighing, axle load monitoring

- Agriculture: Silo weighing, feed control

- Healthcare: Hospital beds, patient lifts, infusion monitoring

- Manufacturing: Force testing, robotics, automation

- Aerospace & automotive: Component testing, material fatigue analysis

How to Choose the Right Load Cell

When selecting a load cell, consider the following factors:

- Capacity: Maximum load to be measured

- Mounting configuration: Tension, compression, shear, or combined

- Environment: Exposure to moisture, dust, or chemicals

- Accuracy requirements: Resolution and tolerance for your application

- Legal-for-trade: If used in commercial transactions, must comply with metrology regulations

Conclusion

Load cells are at the heart of every accurate weighing system. Whether you're weighing vehicles, dosing materials, or testing structural components, choosing the right type of load cell ensures performance, safety, and precision. From single-point sensors in shop scales to multi-ton canister load cells in truck weighbridges, there's a solution for every industrial need.

Need help selecting the ideal load cell? Contact our team of weighing specialists for expert guidance and certified solutions tailored to your industry.

Looking for the ideal load cell for your weighing application?

At Weighing Review you will find articles and other contents about all type of scales and other weighing solutions such as technical articles, videos, case studies and guides. You can also search the Suppliers Directory and Marketplace to find the best supplier and product for your weighing needs.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.